Culverts are an important component in civil engineering projects and water management infrastructure. Notably, they help to manage water flow in areas where there are roads, railways, and other structures. By diverting water into and through structures like culverts and storm drains, we can mitigate flooding and flood damage to our infrastructure. This protects the structural integrity of that infrastructure, and the safety of those who use it. In this post, we look at the 2 main types of culverts, namely the box culvert and the slab culvert and explain their purpose, differences, and benefits.

What is a Box Culvert?

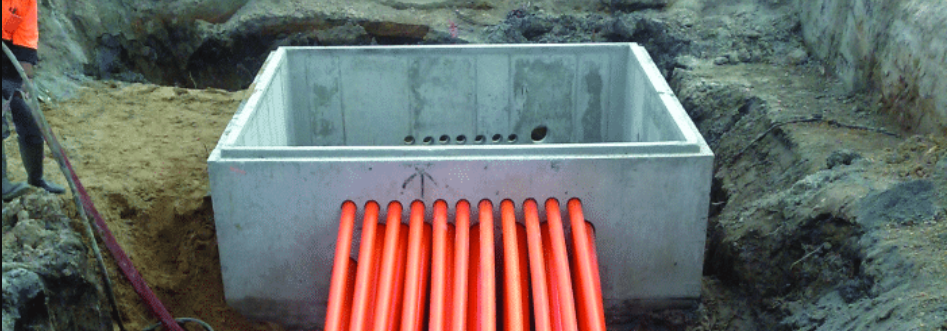

A box culvert is a common and popular type of culvert because it offers strength and structural integrity. It can be either 3-sided (also called a bridge or deck slab culvert) or 4-sided. Civilmart box culverts are precast concrete, 3-sided rectangular shaped units. They come in 2 versions:

- The crown box culvert (looks like a lower case ‘n’ with a flat top and sits on a concrete base slab or similar foundation)

- The inverted box culvert (looks like a ‘u’ with a flat bottom and has a precast concrete lid),

When installed, box culverts create a tunnel underneath infrastructure (roads, railways etc) to allow storm water and other fluids to flow freely without damaging the infrastructure on top. They’re also designed to withstand the weight of the overhead backfill and infrastructure – vehicles, pedestrians, livestock etc.

Box culvert sizes vary – our large precast box culvert for example (manufactured to AS1597.2-2013 standards) is designed for inner spans of over 1200mm, or 1.2 metres. Our small box culverts are designed for 300 – 1200mm spans and manufactured to AS1597.1-2013 standards. Both are made from heavy-duty precast 50MPa concrete.

NB: when talking about box culvert specifications:

- ‘inner span’ is the inside width between the sidewalls,

- ‘width’ is the outside width between the outer edges of the sidewalls,

- ‘length’ is its outside end to end measurement,

- ‘height’ is the outside height of the culvert from the ground to the top of the crown,

- ‘thickness’ refers to the width of the sidewalls,

- ‘crown’ is the top of the culvert and is measured by how thick it is,

- ‘inner leg’ measurement is the internal height of the unit,

- ‘culvert fill height’ is the height of the fill over the top of the box, including the finished road pavement.

What is a Box Culvert Used For?

The durability, longevity, and load bearing capabilities of precast concrete box culverts, like our BCP Precast box culverts, make them suitable for a wide range of applications. They are particularly suited for applications where the surrounding soils are soft and the weight of the culvert and overlying structure needs to be evenly distributed over a wide area.

For that reason, you’ll often find box culverts used in stormwater and drainage management systems around infrastructure like roads and railways, or wherever there is a need to move water around or through structures without compromising drainage. However, they also come in handy for building underpasses, bridges, stock and wildlife crossings, and in industrial ducting applications. We’ve even had customers use them to build emergency escape routes!

Box culverts can be installed in various ways depending on requirements and the nature of the surrounding soils and geology. Our culverts come with a 0 – 2 metre fill height rating so can be buried with only their entrances visible (we also custom manufacture culvert headwalls to suit for both industrial and domestic use.) Alternatively, they can be installed with sections exposed above ground using culvert wingwalls and a base culvert slab or slabs, along with in-situ foundations and apron pours.

Multiple box culverts can also be installed to create larger structures over bigger water flows. In these instances, the boxes may be spaced out with gaps between them to create an interlocking series of box and slab culverts i.e. the ‘gaps’ are turned into slab culverts by adding a purpose-built link slab over the top. Civilmart large and small link slabs are specifically designed for joining box culverts in this way. They are manufactured from reinforced precast concrete to meet AS1597 standards and provide a cost-effective solution for creating larger culvert structures.

What is a Slab Culvert?

A slab culvert is a single horizontal reinforced precast concrete slab supported by abutments or piers. Because it doesn’t have sidewalls, a slab culvert is typically better suited to lower weight-bearing applications and smaller spans in areas with harder soils and geology. Some advantages of slab culvert installation include a more straightforward design, inconspicuous look compared to box slabs, and cost-effectiveness.

What Is a Slab Culvert Used For?

Slab culverts are often used to build low traffic or low weight-bearing crossings over small to medium sized waterways with moderate water flow, and where soil type permits. They are also ideal for private properties, in rural areas with low traffic volume, and where a more inconspicuous culvert look is required, or preferred. Slab culverts can also be alternated in a series with box culverts to create a larger more economical structure, as explained above.

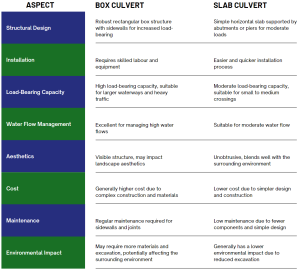

Key Differences in Box Culverts and Slab Culverts

Box culverts and slab culverts have some important key differences that determine their suitability for particular applications.

Box culverts have built-in sidewalls and a top (crowned culvert) or bottom (inverted culvert) and sit on a base plate or concrete foundation (crowned), or have a cover (inverted). This ‘enclosed’ box shape makes them considerably stronger than slab culverts, which rely on the strength and integrity of independent buttresses or pillars for support. They can therefore withstand heavier loads, and are more suitable for wider spans and larger water flows than slab culverts.

Box culverts also distribute weight more evenly across the surface of the underlying ground, an important consideration in softer soils, like those typically found around natural waterways and drainage systems. However, box culverts are more complicated to install than slab culverts, and more expensive both to purchase and install.

Why Choose Civilmart for Your Box Culvert Supplies

When it comes to sourcing and using the best deck slab culvert or box culvert supplies for your infrastructure projects, Civilmart stands out as a reliable and trusted partner. We have many years of civil engineering experience and an unparalleled commitment to excellence and customer service. Our code compliant, precisely engineered precast box culverts and components meet and exceed the highest industry standards, which is why they’re the preferred choice for statutory bodies like VicRoads. Contact us today and discuss your box culvert details and requirements with one of our experienced specialists.