Bernoulli’s principle states that as a liquid’s flow speed, or velocity, increases, its pressure decreases. This is the principle behind orifice plates. In this post, we explain what an orifice plate is, why they are used across a range of industrial applications, how they work, how to install one, and how to work out which orifice plate best suits your application.

What Are Orifice Plates And Why Are They Important?

Orifice plates are very common devices, utilised to control and measure flow of liquids, vapours, and gases.

When applied to Orifice plates, the terms control and measure go hand in hand. By controlling a flow, you can measure the flow rate. The calculation of flow rate would be determined by calculating the difference between two point of measure (i.e. upstream and downstream locations).

However in certain instances the main requirement for an Orifice Plate is to simple control a flow rate (i.e. discharge rate), as inflow rate is known and the desired outflow rate is pre-determined (i.e. must be achieved). Therefore in these circumstances an Orifice Plate acts as a ‘flow regulator’ (i.e. control device), rather than a measuring device.

Although Orifice Plates can be constructed from a variety of materials to assist with controlling and measuring the flow of various liquids, vapours, and gases, the scale of these devices and the materials used to construct them can vary. In its simplest for an Orifice Plate can be made from thin sheet of material – such as a steel plate – and would have a hole in the centre.

The hole can be thought of as an aperture of a specific shape and size to allow for the successful control and/or measurement of a specific liquid, vapour or gas that passes through it. The sheet of material (or plate) would be located directly in the flow path of the target liquid, vapour or gas, so as to force the specific material to interact (pass through) the Orifice Plate.

How Do Orifice Plates Work?

The orifice plate is placed perpendicular to the direction of flow in a pipe where it changes the flow dynamics of the fluid. This alteration provides data that engineers and scientists can use to calculate its flow rate.

Orifice plates are important in a range of engineering and scientific applications because they are:

Accurate

A properly calibrated and installed orifice plate is very accurate.

Simple And Easy

Sometimes things don’t need to be complicated to work well. Orifice plates are a good example. They are simple in design, easy to manufacture, easy to install, easy to use, and easy to maintain.

This being said, the industry or a particular project may require very specific control or measuring in a given application. Therefore the level of technology, materials and performance can increase depending on the desired outcome

Versatile

Orifice plates can be used to measure a wide range of fluids in all their various formats – liquid, vapours, or gas.

They can be designed with a certain shape, material or performance in mind to ensure the results required are achieved.

Cost-Effective

Orifice plates are inexpensive in comparison to some other far more sophisticated flow measurement devices and work just as well. However Orifice plate is a very generic term for a ‘flow regulation’ device, and some highly technical solutions may use this interchangeable name.

Understanding The Basics Behind Orifice Plate Flow Measurement and Control

As mentioned previously, an orifice plate is a thin plate of steel with a hole in the middle. When the plate is placed at right angles to the direction of fluid flow in a pipe, it obstructs the flow of the fluid resulting in reduced velocity and build-up of pressure behind the plate.

The fluid then flows through the hole in the plate. As it does, it picks up speed again i.e. increases in velocity and decreases in pressure. The decrease in pressure is directly proportional to the flow rate of the fluid.

How Does Orifice Plate Measure Flow?

Pressure tappings, or taps, installed downstream and upstream of the orifice plate measure the difference in fluid pressure before and after the plate. Engineers and scientists can then use this information to calculate the flow rate. The precise calculations they use are beyond the scope of this article but involve either Bernoulli’s equation or various other empirical formulas.

How Does an Orifice Plate Control Flow?

When an orifice plate is put into a flow path, the hole in an orifice plate simply restricts the ability of a liquid, vapour or gas to easily pass through to the other side. By acting as a restriction, upstream liquid, vapours and/or gases can be ‘held back’. In certain circumstance can be advantageous particularly where the downstream network (i.e. pipes) can’t handle a large increase in volume of liquid, vapours and/or gases, and therefore the release of these must be controlled over time (i.e. released slowly over seconds, minutes, hours or days).

To achieve this, there must be sufficient upstream storage volume to contain the expected flow of liquid, vapours and/or gases prior to passing through the orifice plate. Storage vessels and orifice plates themselves must also be designed to handle the increased pressure due to the additional volume temporarily stored within.

Types Of Orifice Plates

Concentric and eccentric orifice plates are widely used across several industries. Segmental and quadrant orifice plates, although also common, are more specialised in their application

- Concentric orifice plates have a centrally located hole in the middle for measuring clear/clean fluids in straightforward flow conditions. They are used for a range of general flow measurement applications due to their simplicity, ease of installation, and cost-effectiveness.

- Eccentric orifice plates are designed to measure viscous fluids, fluids with sediment, vapours with a propensity to condense and so on. They have an offset hole that can be positioned to suit the type of fluid being measured. For example, placing it at the top allows gases and vapours to flow through unimpeded so they don’t impact fluid pressure and measurement accuracy. Placing it at the bottom lets sediments continue through without impacting the operation of the plate on the fluid above them.

- Segmental, or segmented, orifice plates have a semicircular hole. Like eccentric orifice plates, they are used for measuring fluids that contain sediments.

- Quadrant, or quarterant, orifice plates look similar to concentric plates with a central hole but the edges of the hole are rounded rather than flat. They are mostly used to measure smooth, uninterrupted fluid flows i.e. those that have a low Reynolds number*.

In addition to these basic designs, there are also variations in the edges of the holes for different applications and fluid types. A plate may, for example, have a square or sharp edged hole (suitable for a wide range of flow types), a rounded edge hole (for measuring calm flows), or a tapered edged hole for measuring turbulent (high Reynolds score) water flows.

* The Reynolds number defines whether a fluid flow is smooth (low) or turbulent (high).

Installing Orifice Plates

The accuracy of orifice plates as flow measurement tools depends as much on the accuracy of installation as it does on the calibration of the plate itself. In this section, we provide some basic ‘how to install orifice plate’ information.

This scenario is based on a ‘standard’ orifice plate installed in a pipe. It should be noted that orifice plates can be install in tanks or pits and therefore installation assumptions outlined below may vary for these circumstances.

Select The Location For The Plate

Choose the location for the orifice plate, factoring in pipe diameter, flow conditions, maintenance accessibility, and nearby fittings or bends that could influence fluid flow.

For preference, choose a long, straight section of pipe with a perfectly round profile. Alternatively, allow a minimum of 5 pipe diameters on both sides of the plate to ensure flow stability (i.e. if the pipe is 40mm in diameter, there should be at least 200mm of straight pipe on either side of the plate).

Pipe Preparation

Thoroughly clean and prepare the pipe – debris, pitting, and other build-up can affect flow measurement accuracy so should be removed.

Plate Installation

Position the orifice plate at right angles to the flow of fluid in the pipe with the sharp edges or throat side of the hole facing the oncoming flow.

Fasten it in place between two flanges, using clamps and bolts to hold it securely.

Pressure Tap Installation

Install pressure taps on either side of the plate. Position them correctly to ensure accurate pressure readings.

Elevate the orifice plate correctly so the pressure taps are at the right height.

Seal The Join

Ensure a watertight seal around the orifice plate, especially if using clamps or flanges. This may require gaskets.

Differential Pressure Transmitter

Install a differential pressure transmitted downstream from the plate to measure the pressure drop accurately and calculate the flow rate.

Plate Calibration

Calibrate both the plate and the differential pressure transmitter as per manufacturer instructions.

Typically, calibration involves running a known volume of fluid through the plate and measuring the resulting pressure drop.

What Are Orifice Plates Used For?

The simple answer is that they are used to measure fluid flow in a pipe. More specifically, they are used to perform a range of measurements in situations where real-time data about fluid quantity, volume, pressure etc is required for operational:

Efficiency

Having accurate flow measurements allow operators to keep processes running at optimal capacity to maximise productivity and minimise waste.

Resource Optimisation

Keeping flow rates running within set parameters optimises resource efficiency, reduces wasteful energy consumption and operational costs, and cuts down wastage of raw materials.

Quality Control

Accurate flow measurements allow for precise ingredient proportions and consistent process conditions, which assists in maintaining consistent product quality.

Compliance

For industries subject to regulatory standards for environmental protection and product quality, accurate flow measurement allows operators to ensure compliance with these standards.

Safety

Monitoring flow rates helps spot potential equipment malfunctions or process abnormalities before they turn into major issues, which helps prevent accidents, and ensures the safety of personnel and assets.

Decision Making

Real-time flow data lets decision-makers make better decisions to optimise processes, troubleshoot problems, and facilitate effective planning.

Different Industries And Uses Of Orifice Plates

Orifice plates are important in industries that deal with liquids, fluids, and gases including:

Different Industries And Uses Of Orifice Plates

Orifice plates are important in industries that deal with liquids, fluids, and gases including:

Water And Wastewater Management

Water management, and wastewater and stormwater treatment systems use orifice plates for a number of reasons such as:

- to provide accurate information about the flow rates of water entering and leaving treatment facilities. In these facilities, orifice plate stormwater and treatment applications include monitoring incoming water flow and measuring outflow to consumers.

- Similarly, industrial wastewater treatment facilities may use a drainage orifice plate to monitor incoming and outgoing wastewater streams. This information is crucial for efficient treatment processing, optimal resource utilisation, and regulatory compliance.

- Where ‘flow regulation’ is required as part of an overarching water management strategy, control of the flow is critical. Therefore Stormwater and Wastewater asset owners use orifice plate type solutions to restrict the volume of liquid discharging into their downstream infrastructure through the containment of upstream liquid volume for a set amount of time.

Oil And Gas

Orifice plates are widely used in the oil and gas industry. Extraction, refining and distribution all require accurate flow measurement data. On the production side, orifice plates measure flow rates from wellheads to processing facilities. In the refining and distribution sectors, they measure flow rates of refined products between units, and entering distribution channels.

The data obtained from orifice plates in these applications is used to optimise production, monitor inventory levels, and ensure compliance with regulatory processes.

Chemical Processing

Precise flow measurements are critical in chemical processing where too much or too little of something can have serious repercussions. Orifice plates are used to accurately measure flow rates of chemicals, raw materials, and solvents, allowing manufacturers to control ingredient quantities. This guarantees consistent product quality, helps maximise output, and ensures optimal processing conditions.

Flow measurements also help with inventory management by providing real-time data on consumption and production rates.

Power Generation

Steam operated power generation relies on accurate flow measurements for efficient operation and safety.

Thermal power plants have orifice plates installed in steam pipelines to measure and monitor the flow rates of steam generated by the turbines and boilers. Without this information, it is almost impossible to know:

- How much steam is being produced and distributed to the various power generation units,

- Maintain reliable and efficient power generation operations, or

- Ensure steam levels are kept at safe operating levels.

How To Determine The Right Orifice Plate For Your Application

To determine the right orifice plate for your application involves consideration of:

Fluid Properties Of The Liquid Being Measured

Fluid properties include the:

- Density of the fluid to be measured. Density is the fluid’s mass per unit, which influences its flow properties and how it will flow through the orifice plate.

- Viscosity – this is the fluid’s resistance to flow. It affects how smoothly it flows through the orifice plate and thus influences the pressure drop as it does so.

The denser or more viscous the fluid (crude oil, viscous chemicals etc) the larger the hole in the orifice plate generally needs to be. The hole may also have special edges to minimise pressure drop and allow accurate flow measurements.

- Temperature – the thermal energy of fluid affects both its density and viscosity. Water with high thermal energy for example turns into steam. Steam and water have different flow behaviours and therefore measure differently.

High temperature fluids, like steam, may require an orifice plate made from heat resistant materials to ensure longevity and accuracy.

Flow Conditions

Flow takes into account the:

- Reynolds Number – this number indicates the type of flow (turbulent or laminar i.e. calm, smooth etc). The lower the number, the smoother the flow.

Flows with a high Reynolds number (stormwater flowing through a stormwater drain / fluids flowing through large pipes or in high-flow rate applications) will need a plate design that minimises flow disturbance and maintains accuracy despite the turbulence. Segmented and quadrant-edge orifice plates are designed for these types of flows.

- Pressure – the fluid exerts pressure on the orifice plate and the difference between this force and the force of the fluid that flows through the hole creates the ‘pressure difference’ used to measure flow.

Orifice plates used in high-pressure flow applications need to be robust enough to stand up to the pressure.

- Temperature – the temperature of the fluid affects its flow characteristics (water vs steam).

Accuracy Requirements

Some applications require a high degree of accuracy whilst others don’t. This will affect the precision level required of the plate – the more precisely engineered it is, the more accurate the measurements will be.

Plates for these applications typically have precise edge profiles to suit the type of fluid being measured.

Installation Constraints

Space limitations – tight spaces may require low profile or compact orifice plates.

Accessibility for maintenance – install the orifice plate in a location that allows easy access for inspection and maintenance.

Pipe size – selecting the right size orifice plate relative to the diameter of the pipe is crucial. Large pipes can often use standard orifice plate designs, depending on fluid type but smaller pipes may need compact or segmental plate designs.

How to size an orifice plate: ISO 5167 contains the flow equations and standards typically used to size orifice plates accurately for any given application. But in general, the process is to:

- Establish the pipe diameter and fluid properties.

- Calculate the desired flow rate and pressure drop.

- Select the appropriate orifice plate size based on flow conditions and accuracy requirements.

- Verify compliance with relevant standards and regulations.

- Install and calibrate the orifice plate for accurate measurement.

Why Choose Civilmart for Your Orifice Plate Needs?

Choosing Civilmart for your orifice plate needs is a wise choice. We offer comprehensive solutions backed by quality products, expertise, and a long history of driving customer satisfaction.

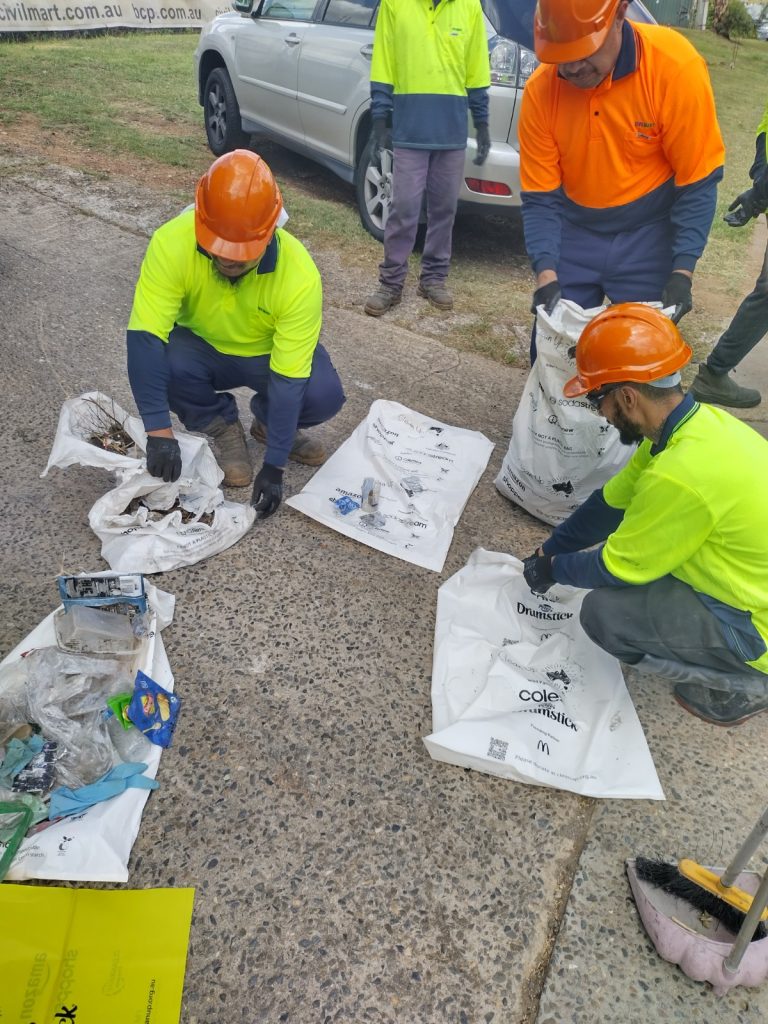

Civilmart through our technology partners are able to offer the Hydro-Brake® Flow Control device to the Australian market. This system is an ideal product solution for controlling flow of stormwater entering or exiting a larger system or infrastructure network. We have successfully installed Hydro-Brake® Flow Control devices within On-Site Detention (OSD) systems and well as stormwater treatment devices – such as our Gross Pollutant Trap (GPT) range.

Our commitment to reliability and durability means our customers can trust us to deliver long-term performance solutions for even the harshest conditions. Further, a focus on customer satisfaction, timely delivery, and competitive pricing, coupled with industry regulation and standards compliance makes us a trusted partner for all your stormwater and drainage solutions. Contact us today to discuss your stormwater draining flow measurement requirements.