Let’s delve into the realm of concrete railway sleepers. We’ll explore their advantages, the various classifications available, the installation process, strategies for upkeep, their diverse range of uses, and the rationale behind considering them as the preferred option.

Railway sleepers, or ties, are long rectangular support beams used in railway lines to provide a level and standardised base for the rails. Whilst wooden sleepers are still used on lines in some parts of the world, elsewhere they’re often replaced with stronger, more durable precast concrete sleepers with steel or fibre reinforcing. However, concrete sleepers are not a new development. They’ve been used in railway construction in Europe and the US since the late 1800’s and are now the industry standard in countries like Australia thanks to their low maintenance requirements and durability. We highly recommend high-quality concrete sleepers to ensure the safety and longevity of your project.

Benefits of Concrete Railway Sleepers

Concrete sleepers have many benefits over the use of traditional wooden sleepers. The most obvious is durability and longevity. Good quality precast concrete sleepers, like those we produce at Civilmart, will last 50 or more years. Additionally, our concrete sleepers are also:

Low maintenance

Reinforced concrete has replaced timber and steel as a preferred construction material in many applications because requires much less maintenance over extended periods of time.

High Load-Bearing Capacity

Our reinforced concrete sleepers are suited for heavy-duty applications, like withstanding the weight and pressure of high-speed trains without flexing or warping. Our unique, one of a kind Multilok™ system further allows rails to be rotated and adjusted laterally on site without drilling. They also prevent rail drift and being heavy, can be anchored securely in railway ballast.

Cost effective

Although more expensive initially, concrete sleepers have a much longer life-span and require far less maintenance than other types of sleepers. Ultimately, they’re far more cost-effective in the long term.

Fire Resistant

In climates like Australia we are often impacted by large bushfires. Concrete sleepers are flame resistant which assists with keeping our infrastructure intact if a natural disaster takes place.

Rust Resistant

Unlike sleepers manufactured with steel or other metals, concrete sleepers won’t rust when exposed to the weather.

Rot, Termite, And Pest Resistant

Concrete sleepers won’t rot over time like wooden sleepers. They also won’t be impacted by pests such as termites, which also means there’s not need for regular pesticide treatments.

Different Types of Sleepers

You may think concrete railway sleepers come standard but in reality there are a number of different types of Australian concrete sleepers designed to cater to different needs and aesthetics.

Standard Concrete Sleepers

These are the most common. Civilmart’s concrete sleepers are sturdy and durable, and can withstand the weight and pressure of most applications.

Coloured Concrete Sleepers

Concrete sleepers can be permanently tinted during the manufacturing process to make them blend in, or stand out. Civilmart makes a line of strong durable sleepers designed for creative purposes like retaining walls.

Patterned Concrete Sleepers

These are another popular option for gardens and landscaping. The various shapes and textures of patterned concrete sleepers add interest and character to an environment.

Timber-Look Concrete Sleepers

If you want the traditional wooden sleeper look with the benefits of concrete, and minus the maintenance of wood, these are a good choice.

Hollow Concrete Sleepers

These are a lightweight but strong, durable sleeper with a hollow core. They’re great for gardens and landscaping where a traditional sleeper look is required minus a traditional concrete sleepers weight! Being lighter, they’re easier to move around and install.

Maintenance of Concrete Sleepers

One of the real advantages of concrete sleepers is their low maintenance. However, that doesn’t mean they’re totally maintenance free, although the level of maintenance does depend on where they’re used.

Regular Cleaning

Clean landscaping sleepers regularly to maintain their crisp, sharp look. In railway line applications, inspect sleepers on a regular basis to clean away debris build-up, and to check for damage. Both can compromise the safety of the railway line.

Repair Minor Damage

Most minor damage to concrete sleepers, like small cracks, chips, and factures, can be repaired in situ using special resins, concrete mixes, bonding agents, and reinforcing bars. If you are repairing a sleeper on your property, follow the manufacturer’s instructions for applying the repairing agents.

Repairing sleepers in railway lines however is a job for professionals. Bodies like the federal government owned Australian Rail Track Corporation (ARTC) have specific published guidelines around the identification and repair of damaged sleepers.

Prevent Water Damage

Preventing water damage to sleepers is also important, particularly wooden ones. This requires:

- Proper drainage – essential regardless of whether it’s landscaping or a railway line. Good drainage redirects water away from the sleepers preventing rot (wooden sleepers) and ballast/soil erosion.

- Good ballast construction and maintenance – correctly installed, well-compacted ballast along with regular inspections and maintenance (like removing debris that impedes drainage) help prevent water damage.

- Waterproofing treatments – wooden sleepers should be waterproofed to prevent water damage and rot.

- Correct track alignment – correctly aligning and levelling a railway track and using the right ballast helps prevent water pooling around sleepers.

Pest Protection

Wooden sleepers need protection from pests like termites and wood rot fungi so are treated with chemicals like creosote (a biocide), disodium octaborate tetrahydrate, and chromated copper arsenate. Although very effective against termites and other insect pests, there are increasing concerns over the safety and environmental impact of these types of chemicals. Notably, creosote and creosote treated products are no longer used or permitted in domestic and garden applications in Australia.

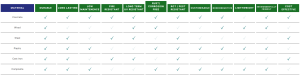

How Do Other Sleeper Materials Measure Up?

What is the best type of sleeper?

Wooden Sleepers

Wooden sleepers are a popular choice for garden and landscaping applications, and are still used in railway lines in many countries. They are strong, flexible, easy to install and maintain. They’re also renewable and easily recyclable. However, they are high maintenance, have a shorter life than other materials, and are prone to rot, warping, insect damage, and fire damage. They also allow rail creep in railway lines as they deteriorate.

Steel Sleepers

Steel sleepers are durable, strong, and long lasting. They are fire resistant, and easy to install and handle, plus prevent rail creep. However, they are more expensive than wood, are susceptible to rust, and corrode over time. They’re also electrically conductive, slippery, and noisy, making them a safety hazard in high pedestrian and vehicle traffic areas like level crossings.

Plastic Sleepers

Plastic sleepers, made from recycled plastics like high-density polyethylene (HDPE), offer advantages such as durability, low maintenance, rot and pest resistance, and are lightweight and environmentally friendly. However, they are also expensive, can break down over time leaving non-biodegradable plastics in the environment, burn in extreme fire conditions, and require more maintenance than Civilmart concrete sleepers.

Cast Iron Sleepers

Cast-iron sleepers offer similar benefits as steel sleepers, although they are more expensive. Like steel, they can also rust and corrode, and therefore require more maintenance than concrete sleepers. They’re also electrically conductive and not suited for use in level crossings.

Composite Sleepers

Composite sleepers are made from mixtures of recycled plastics, wood fibres, fibreglass reinforced polyurethane foam, and waste agricultural plastics. Although they are durable, lightweight, and environmentally friendly they’re also expensive, not completely fire resistance, and being so light, are difficult to anchor securely in railway applications.

With their strength, durability, and low-maintenance qualities, pre-cast concrete sleepers are the smart choice if you’re looking for reliability, longevity, and cost-effectiveness in a sleeper product. Combined with a choice of standard, coloured, patterned, timber-look, or hollow concrete sleepers, you’re sure to find exactly the right type of sleeper to suit your application.

At Civilmart, we are committed to supplying high-quality concrete sleepers for a range of purposes – from railway lines to garden and landscaping applications. So why not choose the best option on the market and invest in Civilmart precast concrete railway sleepers. Contact us today to learn more about our range of products and services or for information about concrete sleepers Canberra, concrete sleepers Victoria, and concrete sleepers NSW.

Join the Civilmart family

Stay up to date with latest product releases, newest industry innovations and more!